Celler Straße 67 - 69

38114 Braunschweig

Germany

Fon: +49 (0) 531-129 399 0

Fax: +49 (0) 531-129 399 29

Mail: info@tbksoft.com

Web: http://www.gwj.de

Plugin for Autodesk Inventor

Features

- It is possible to start all TBK calculation modules directly from Autodesk Inventor through an integrated menu.

- Based on the calculation, external and internal, spur and helical gears can be generated automatically as a feature-based 3D part in Autodesk Inventor.

- Cylindrical gears can be created as a single part or directly on an existing part. During the generation, a tool runout can be developed. For this purpose, the user has to specify an offset (increase of the facewidth) or a radius for the cutter or grinding wheel.

- Based on the calculation, straight, helical and spiral bevel gears can be automatically created as a native 3D part in Autodesk Inventor.

- A simple mouse-click allows to add all necessary manufacturing data of a gear wheel to the drawing. The data is displayed as a table. The appearance and size of that table is individually configurable.

- Solid and hollow shafts with an unlimited number of cylindrical and conical shaft segments can be generated.

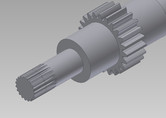

- For serrated and splined shaft connections, the shaft and the hub profile can be generated as native 3D models (single part) based on the calculation.

- Involute splines can be created as a 3D Autodesk Inventor part (single part or directly on existing part) on the basis of the calculated data. With just one click, the design table with all manufacturing details of involute splines can be placed on the drawing as well.

- The calculation information is saved in the 3D model and is available at any time.

- Bidirectional connection between TBK and Autodesk Inventor (shaft, gear, involute spline profile as single part)

- Number of teeth to be generated for cylindrical gears, bevel gears and involute spline profiles can be defined in the option menu.

- Accuracy / distance between points can be specified in the option menu.

- Tooth flanks as splines or alternatively as arcs possible

Description

A single menu pick in the TBK software transfers the TBK calculation data to Autodesk Inventor. All calculation modules can be started directly in Autodesk Inventor.

On the basis of the TBK calculation using the module "Cylindrical gear pair", external and internal spur and helical gears can be created automatically as a native 3D part in Autodesk Inventor. Addendum chamfer, profile shift, tolerances and shaft bore will be considered in the calculation and modelling. The gears include the accurate tooth form. The calculation of the 3D tooth form is conducted according to a mathematical simulation of the manufacturing and rolling process.

The cylindrical gears can be created as a single part or directly on an existing part. During generation, a tool runout can be developed. For this purpose, the user has to specify an offset (increase of the facewidth) or a radius for the cutter or grinding wheel.

Involute splines according to standards such as DIN 5480, DIN 5482, ISO 4156, ANSI B92.2M und ANSI B92.1 can be also created as a 3D part including the accurate gear tooth form.

Based on the calculation, straight, helical and spiral bevel gears can be generated as a native 3D part in Autodesk Inventor.

The CAD model stores all features and dimensions as design parameters. The TBK calculation including all design parameters is saved in the part and can be opened at any time throughout the entire design phase.

The plugin provides a very fast and comfortable generation of 3D shafts. The geometry of the shaft can be defined very easily. A simple mouse-click starts the automatic generation in 3D. Solid and hollow shafts with an unlimited number of cylindrical and conical shaft segments can be created as a 3D part.

The attractiveness of this CAD plugin is additionally enhanced by the bidirectional connection between TBK and Autodesk Inventor. In case changes are required after the calculation and creation of the 3D model, the model can be easily updated based on the modified calculation. This functionality is available for external and internal spur and helical gears, involute splines as well as for hollow and solid shafts. It is a quick and easy way to update 3D models during the development process.

With just one click, the design table with all manufacturing details of cylindrical gears, bevel gears and involute splines can be placed on the manufacturing drawing. The appearance and size of that table is individually configurable. There is no need to manually add all design table parameters to the drawing.

In addition to shafts, gears and involute splines, the generation of serrated and splined shaft profiles is also supported. Based on the calculation, the shaft and the hub profile can be created as a single part in 3D.